X2 Mill

This page documents the setup and modification of the Harbor Freight Mini Mill (Sieg X2 Clone).

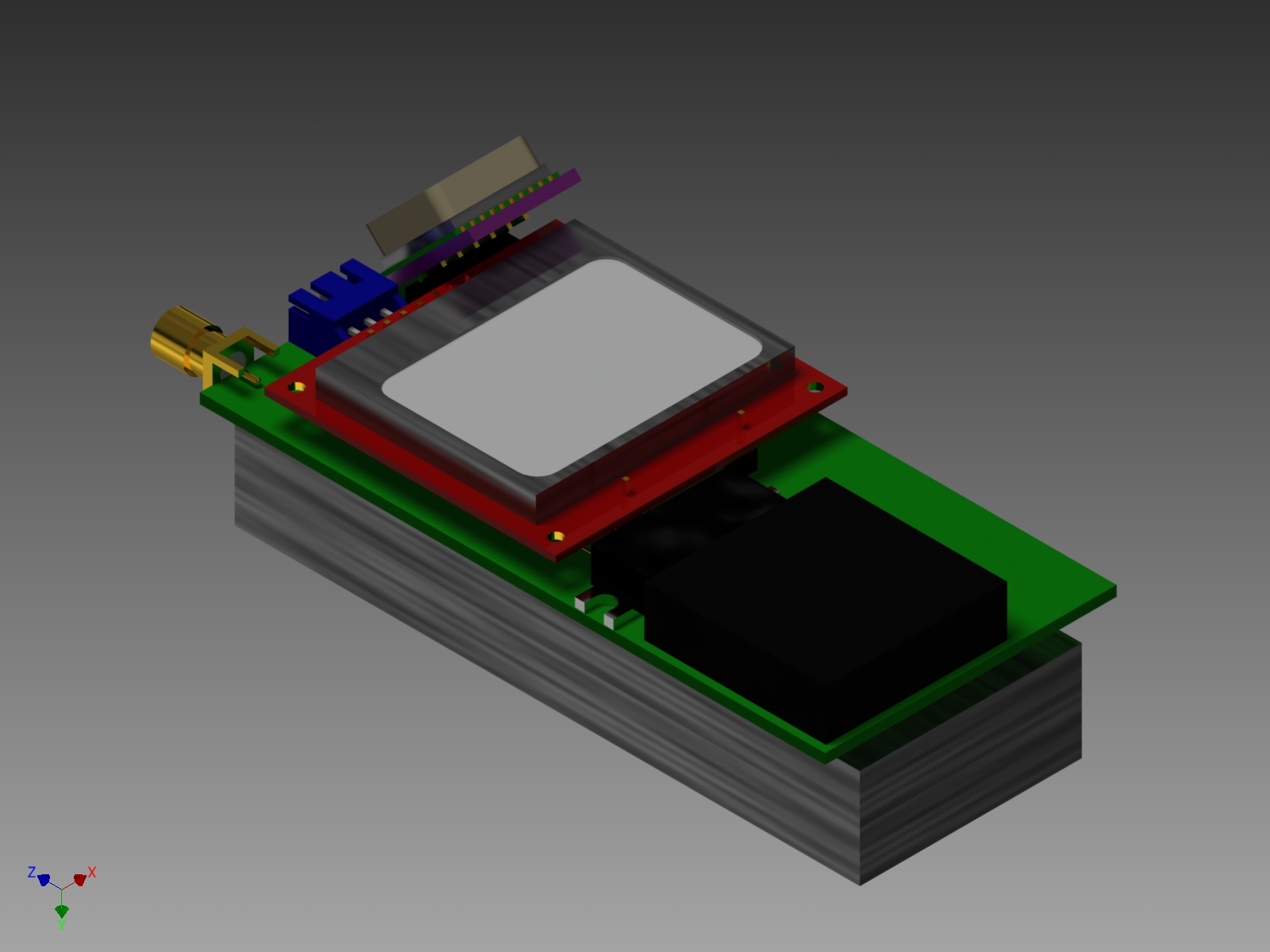

3D Model

...

Setup/Modifications

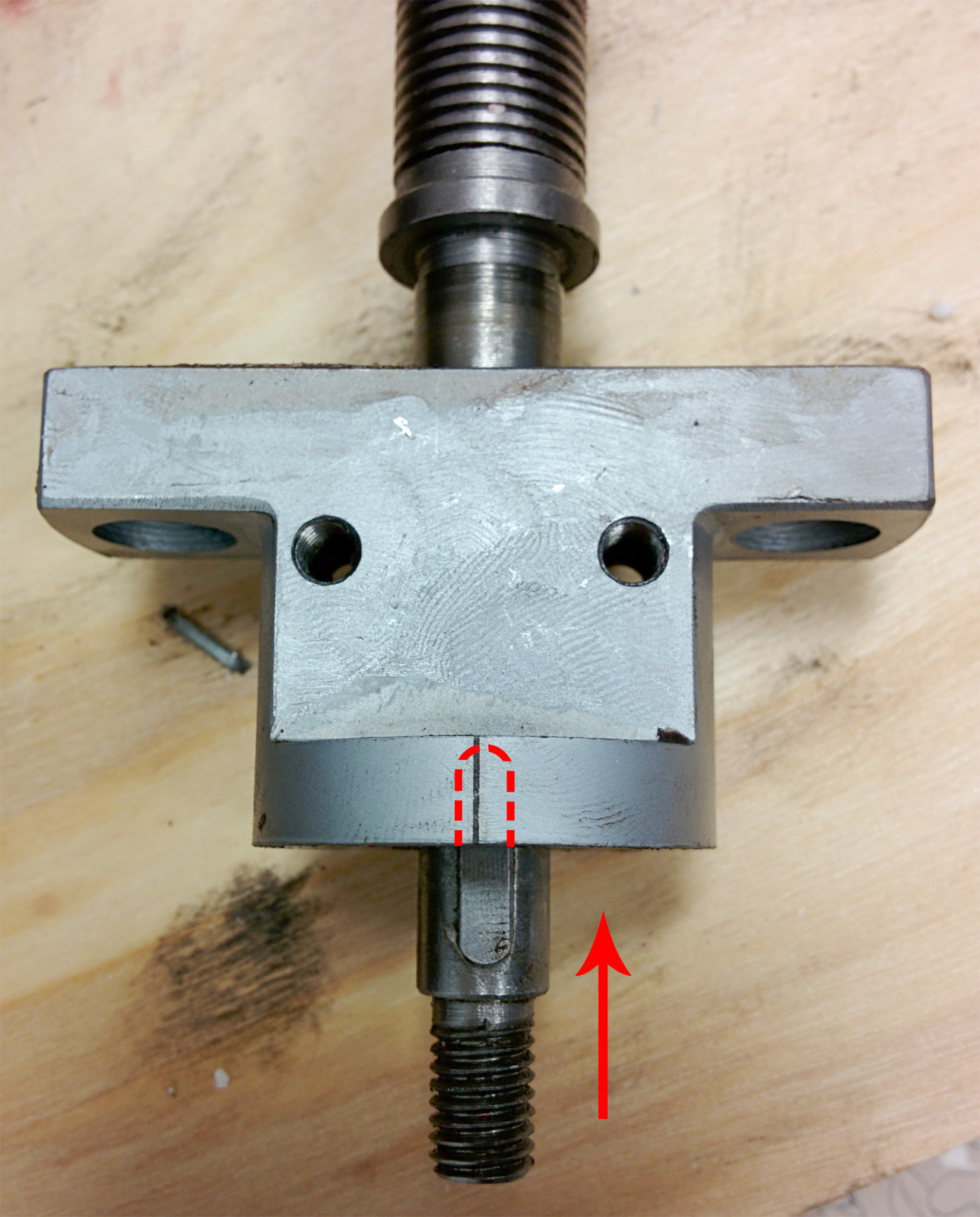

11/12/2012 - Harbor Freight Mini Mill arrives; damaged in shipment, both hold-down bolts came loose and the unit was dropped on the Y axis jamming the notch into the bearing/sleeve thus preventing any movement of the Y axis. Contacted customer service who made a note to return the mill to a local store and get a receipt to place a replacement order.

11/13/2012 - Damaged mill returned to Harbor Freight.

11/16/2012 - Replacement mill ordered by phone, shipping charge was waived since it was not refunded by the store with the damaged unit return.

11/20/2012 - Replacement mill arrives, was only held down with one bolt (which was loose), but undamaged. Stripped down unit, cleaned, and lubricated Y and X axes and adjusted gibs.

11/22/2012 - Stripped and cleaned Z axis/mill head, lubricated and adjusted gibs, and partially mounted unit to bench. Removed power supply box from back as it interfered with the shelf on the bench.

11/30/2012 - Fully mounted unit to bench, re-adjusted gibs.

12/4/2012 - Mounted and squared vise, adjusted motor gear meshing, re-attached baffles, removed drill chuck and attached 3/8" R8 collet. Made first cuts in aluminum (shown below).