X2 Mill: Difference between revisions

No edit summary |

(→Photos) |

||

| Line 49: | Line 49: | ||

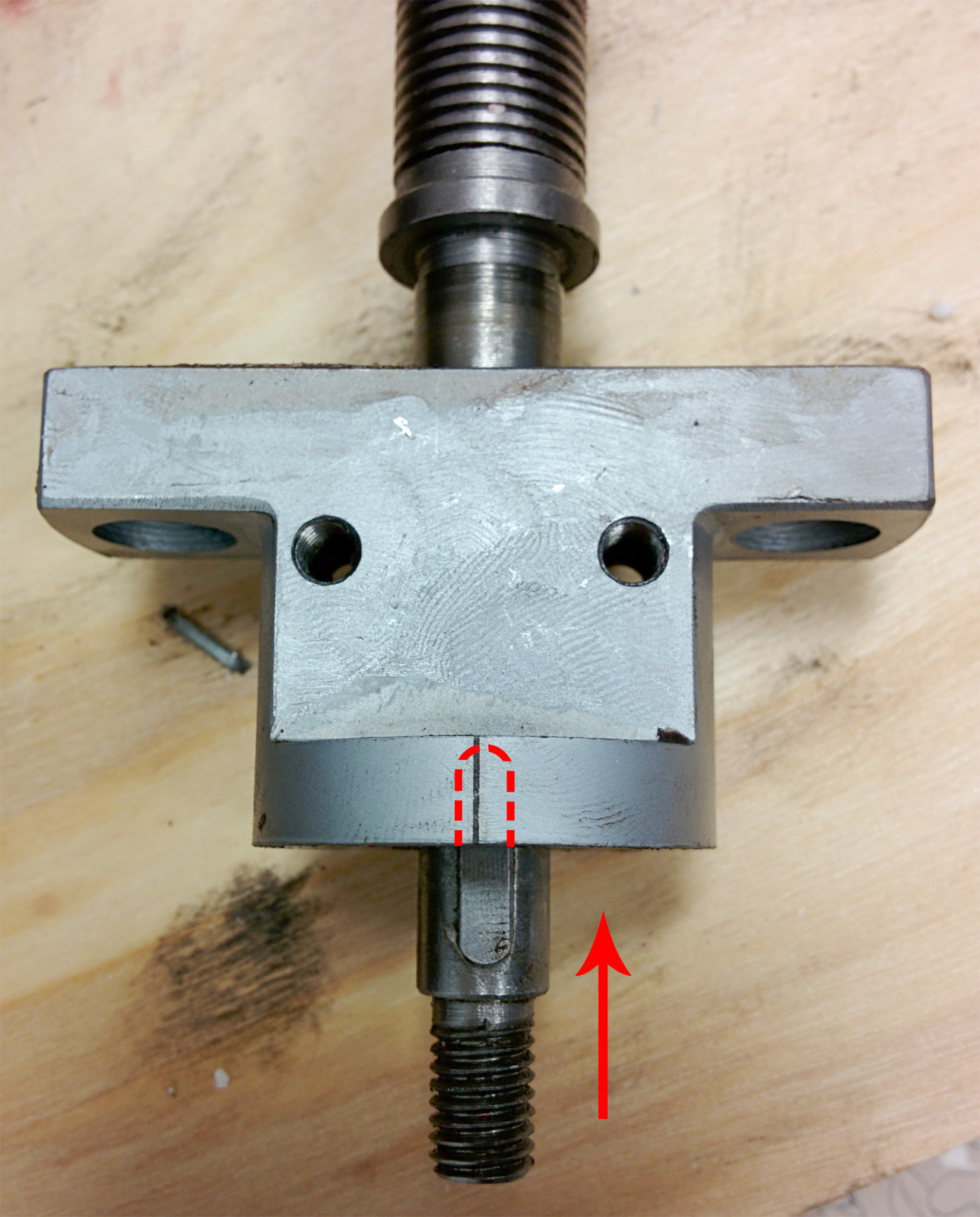

File:Damage.jpg|Damage to Y axis on original mill. | File:Damage.jpg|Damage to Y axis on original mill. | ||

</gallery> | </gallery> | ||

==Resources== | |||

===CNC=== | |||

http://www.hossmachine.info/cnc_conversion.html | |||

http://www.fignoggle.com/plans/cncplans.htm | |||

http://www.mini-lathe.com/Mini_mill/Modifications/Power_feed/power_feed.htm | |||

http://plsntcov.8m.com/grizzley.html | |||

http://www.cncfusion.com/minimill1.html | |||

https://www.ocf.berkeley.edu/~davytong/personal_projects_and_hobbies/mill2.htm | |||

http://www.mendingthings.com/?page_id=503 | |||

===DRO=== | |||

http://www.yuriystoys.com/p/android-dro.html | |||

http://www.yuriystoys.com/p/msp430-launchpad-mixed-scale-dro.html | |||

http://www.cncguns.com/forum/index.php?topic=1471.0 | |||

http://www.rysium.com/projects/189-mini-mill-modifications | |||

https://sites.google.com/site/davemarkowitzsmachineshop/projects/grizzly-g8689-mill-dro | |||

http://www.yuriystoys.com/2014/02/dro-scale-calibration.html | |||

===General=== | |||

http://littlemachineshop.com/info/minimill_compare.php | |||

http://littlemachineshop.com/info/MiniMillUsersGuide.pdf | |||

http://www.littlemachineshop.com/Projects/ViseClamps.php | |||

http://www.cnccookbook.com/CCMillTramming.html | |||

https://lanzerbot.wordpress.com/2014/12/17/stiffening-the-vertical-column-on-the-x2-mill/ | |||

===Upgrades=== | |||

http://littlemachineshop.com/products/product_view.php?ProductID=2258&category= | |||

http://www.cnczone.com/forums/benchtop-machines/55239-x2-timing-belt-drive-cheap-course.html | |||

http://www.cnczone.com/forums/benchtop-machines/111328-20-buck-x2-belt-drive-2.html | |||

http://www.cnczone.com/forums/benchtop-machines/61507-20-00-x2-belt-drive.html | |||

http://www.fignoggle.com/kits/acme-leadnuts.htm | |||

Revision as of 23:28, 8 December 2015

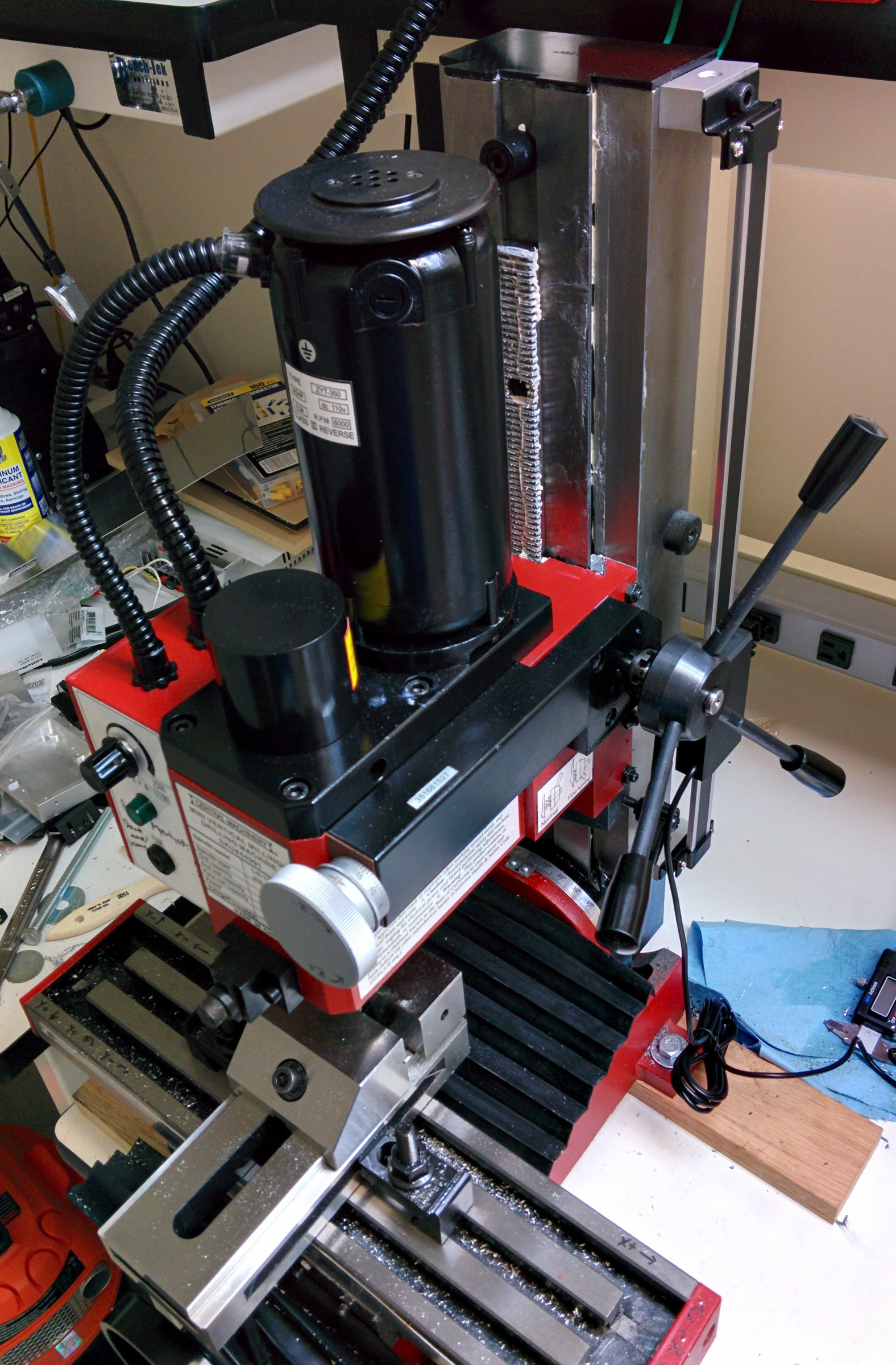

This page documents the setup and modification of the Harbor Freight Mini Mill (Sieg X2 Clone).

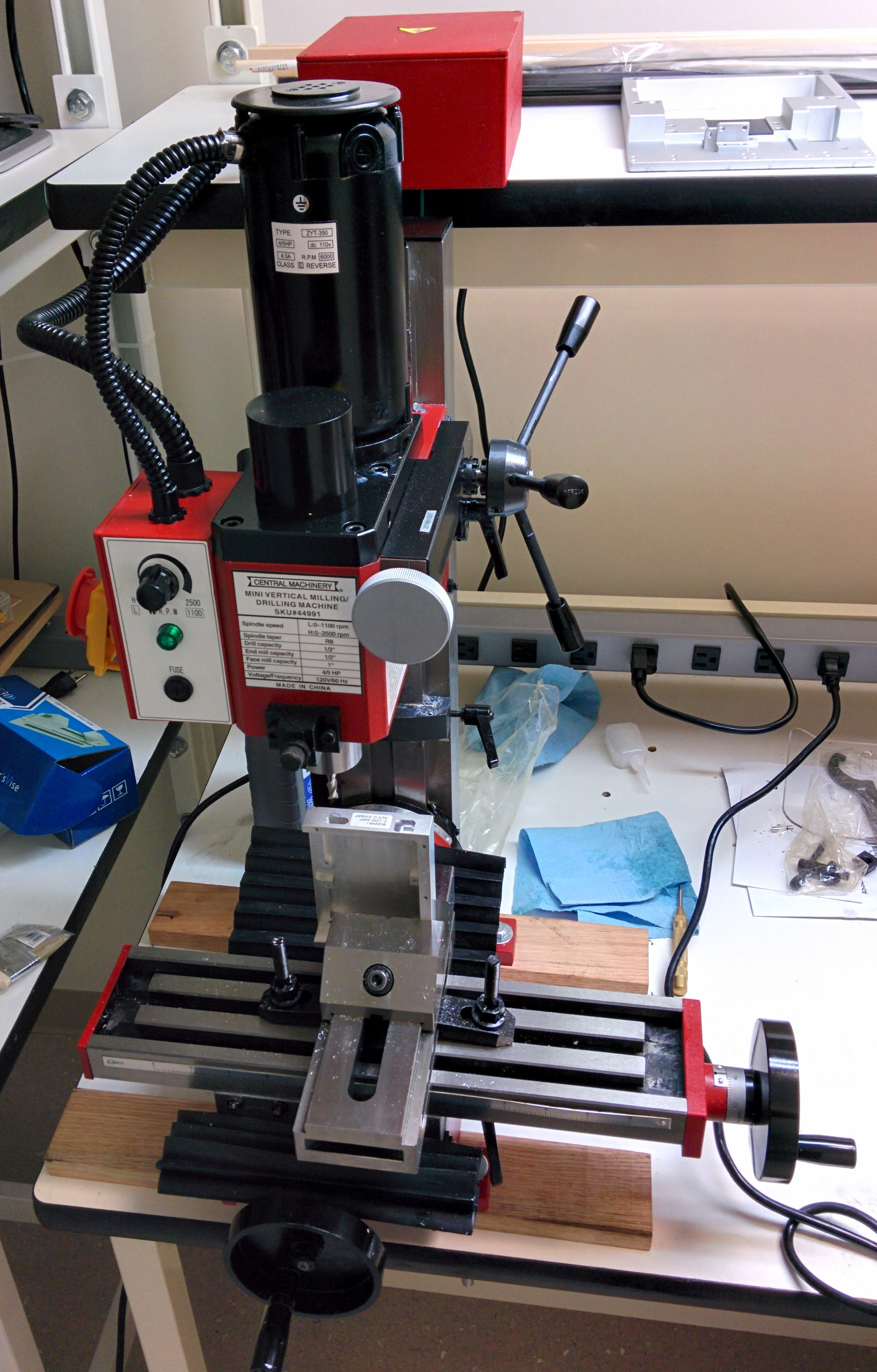

==General In The Harbor Freight Mini Mill (SKU 44991) is a clone of the Sieg X2 Mini Mill. It is one of various clones of the Sieg X2 on the market, including others by Grizzly, Little Machine Shop, Micro Mark, etc. The Harbor Freight variant has a variable speed 350W DC motor with 2 gear ranges for 0-1100 or 0-2500 RPM, and an R8 taper spindle. The mill has a tilting column with -45 to +45 degree range, and has a tension spring supported mill head. The main table is 3-5/8″ x 15-3/4″, and has a total X travel of 9″, Y travel of 4", and Z travel of 8-1/2". The X and Y dials have 62.5 mils per turn with 1 mil graduations. The Z dial has 60 mils per turn with 1 mil graduations.

3D Model

A 3D CAD model of the Sieg X2 along with CNC additions is available at GrabCAD here: https://grabcad.com/library/sx2-mini-mill-cnc

Setup/Modifications

11/12/2015 - Harbor Freight Mini Mill arrives; damaged in shipment, both hold-down bolts came loose and the unit was dropped on the Y axis jamming the notch into the bearing/sleeve thus preventing any movement of the Y axis. Contacted customer service who made a note to return the mill to a local store and get a receipt to place a replacement order.

11/13/2015 - Damaged mill returned to Harbor Freight.

11/16/2015 - Replacement mill ordered by phone, shipping charge was waived since it was not refunded by the store with the damaged unit return.

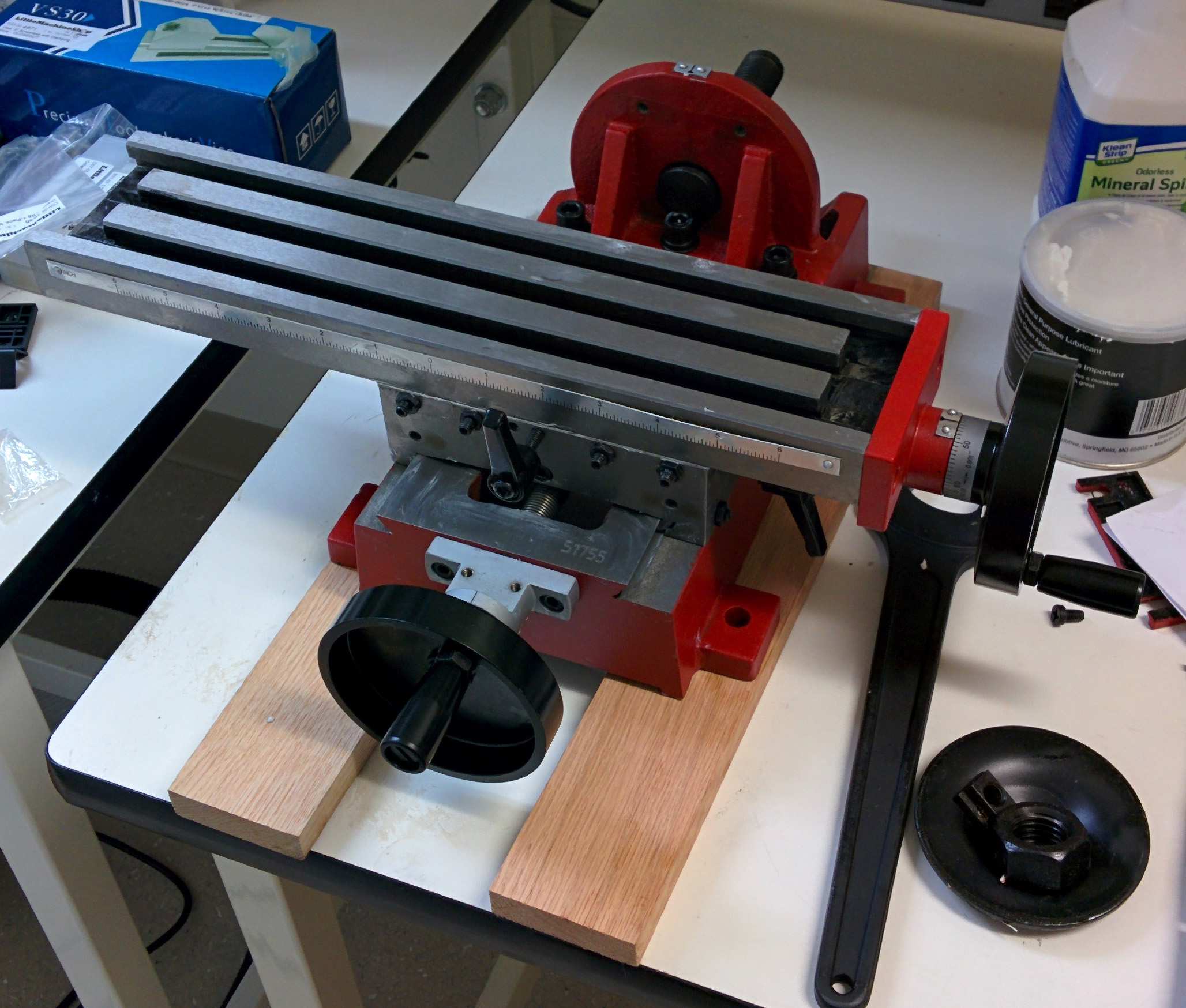

11/20/2015 - Replacement mill arrives, was only held down with one bolt (which was loose), but undamaged. Stripped down unit, cleaned, and lubricated Y and X axes and adjusted gibs.

11/22/2015 - Stripped and cleaned Z axis/mill head, lubricated and adjusted gibs, and partially mounted unit to bench. Removed power supply box from back as it interfered with the shelf on the bench.

11/30/2015 - Fully mounted unit to bench, re-adjusted gibs.

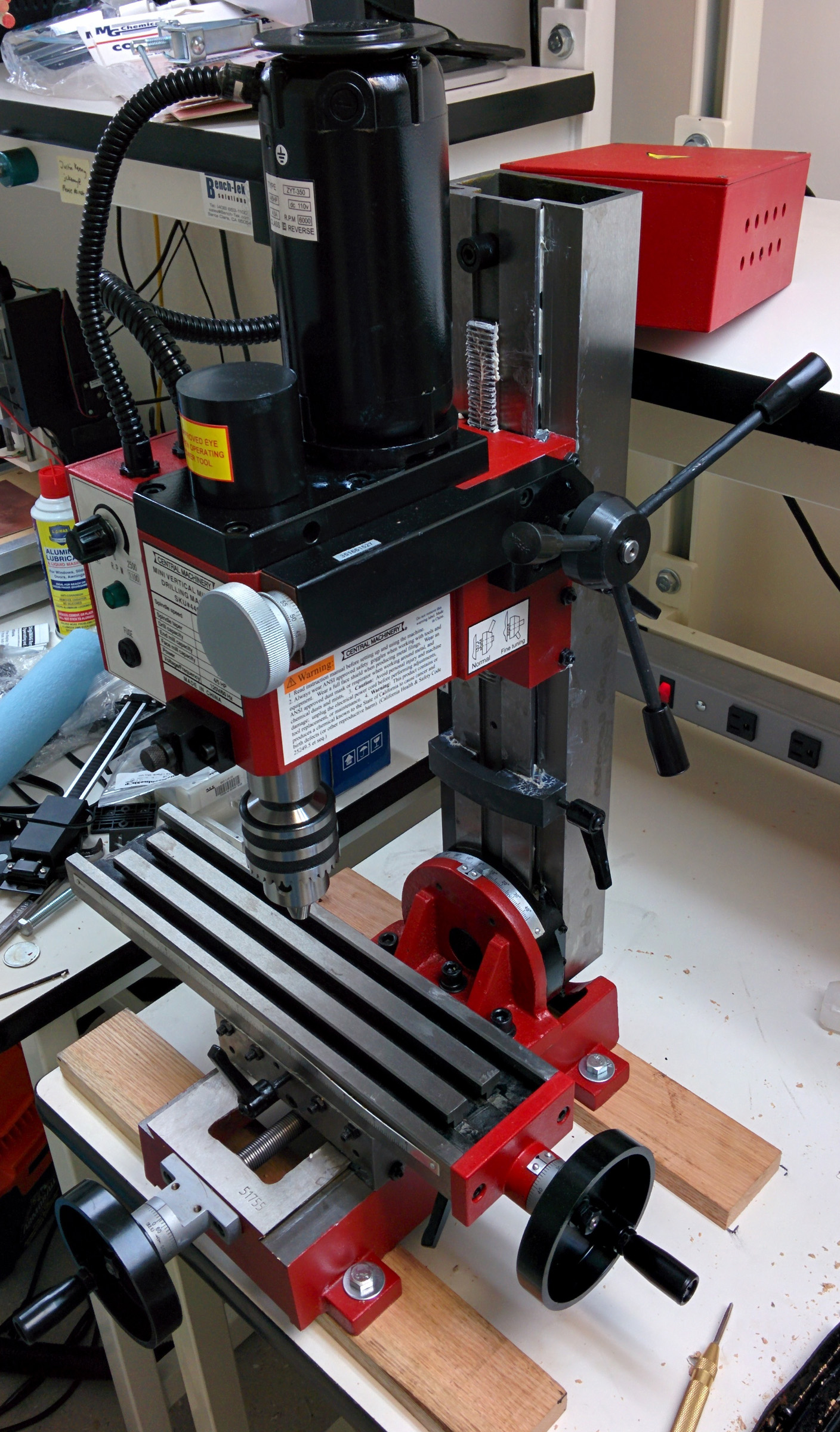

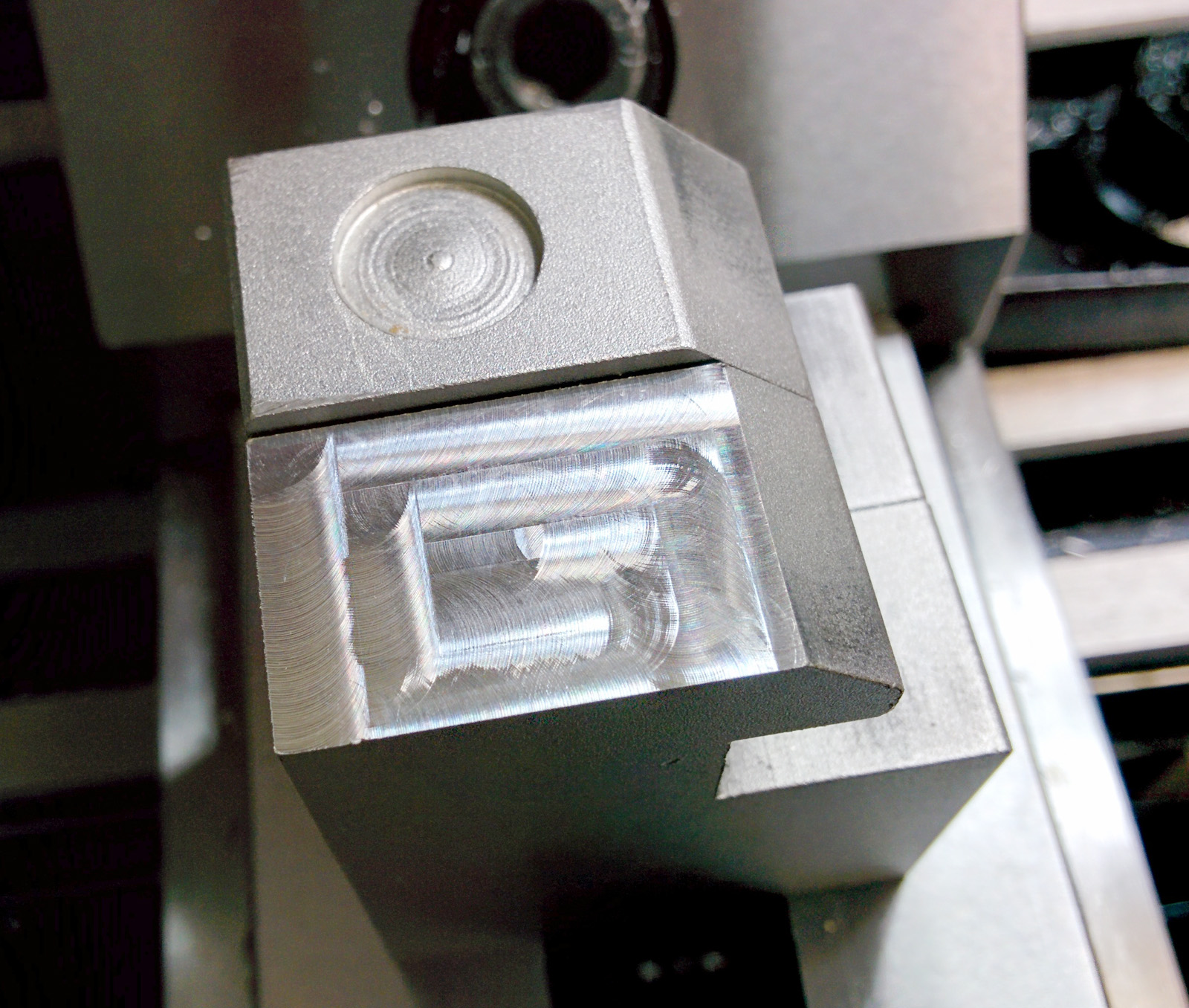

12/4/2015 - Mounted and squared vise, adjusted motor gear meshing, re-attached baffles, removed drill chuck and attached 3/8" R8 collet. Made first cuts in aluminum (shown below).

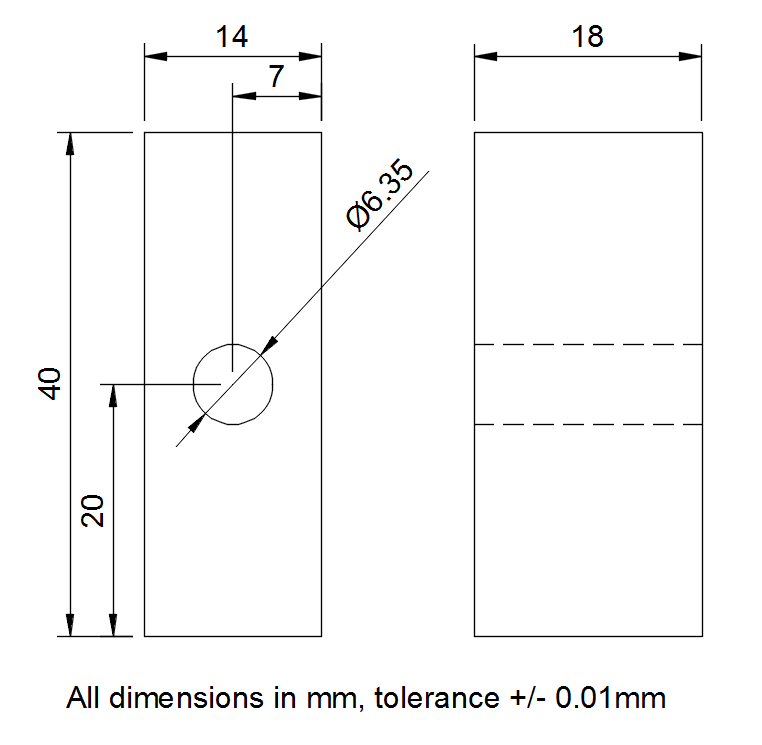

12/7/2015 - Milled holes in 2 aluminum pieces to be used as spacers for mounting the Z-axis DRO. Drilled and tapped 2 M6 holes in mill column, mounted Z-axis DRO fixed portion. Mounted vise properly using step blocks.

Photos

Resources

CNC

http://www.hossmachine.info/cnc_conversion.html http://www.fignoggle.com/plans/cncplans.htm http://www.mini-lathe.com/Mini_mill/Modifications/Power_feed/power_feed.htm http://plsntcov.8m.com/grizzley.html http://www.cncfusion.com/minimill1.html https://www.ocf.berkeley.edu/~davytong/personal_projects_and_hobbies/mill2.htm http://www.mendingthings.com/?page_id=503

DRO

http://www.yuriystoys.com/p/android-dro.html http://www.yuriystoys.com/p/msp430-launchpad-mixed-scale-dro.html http://www.cncguns.com/forum/index.php?topic=1471.0 http://www.rysium.com/projects/189-mini-mill-modifications https://sites.google.com/site/davemarkowitzsmachineshop/projects/grizzly-g8689-mill-dro http://www.yuriystoys.com/2014/02/dro-scale-calibration.html

General

http://littlemachineshop.com/info/minimill_compare.php http://littlemachineshop.com/info/MiniMillUsersGuide.pdf http://www.littlemachineshop.com/Projects/ViseClamps.php http://www.cnccookbook.com/CCMillTramming.html https://lanzerbot.wordpress.com/2014/12/17/stiffening-the-vertical-column-on-the-x2-mill/

Upgrades

http://littlemachineshop.com/products/product_view.php?ProductID=2258&category= http://www.cnczone.com/forums/benchtop-machines/55239-x2-timing-belt-drive-cheap-course.html http://www.cnczone.com/forums/benchtop-machines/111328-20-buck-x2-belt-drive-2.html http://www.cnczone.com/forums/benchtop-machines/61507-20-00-x2-belt-drive.html http://www.fignoggle.com/kits/acme-leadnuts.htm