CCR: Difference between revisions

(→Photos) |

No edit summary |

||

| Line 157: | Line 157: | ||

==Electronics== | ==Electronics== | ||

[[File: | [[File:tbd.png|thumb|right|The complete system schematic for the CCR v1.0.]] | ||

===Buck Converter (Charger)=== | ===Buck Converter (Charger)=== | ||

| Line 196: | Line 196: | ||

==Enclosure== | ==Enclosure== | ||

The enclosure for the | The enclosure for the CCR v2.0 was created in Fusion 360 and is made up of x pieces which can be 3D printed and assembled with M3 screws. | ||

Here are the | Here are the Fusion 360 files for the CCR v2.0 enclosure: http://rev0proto.com/files/tbd.zip | ||

==Code== | ==Code== | ||

Full source code for the project can be found here: http://rev0proto.com/files/ | Full source code for the project can be found here: http://rev0proto.com/files/x.zip | ||

==Videos== | ==Videos== | ||

Revision as of 23:00, 10 January 2019

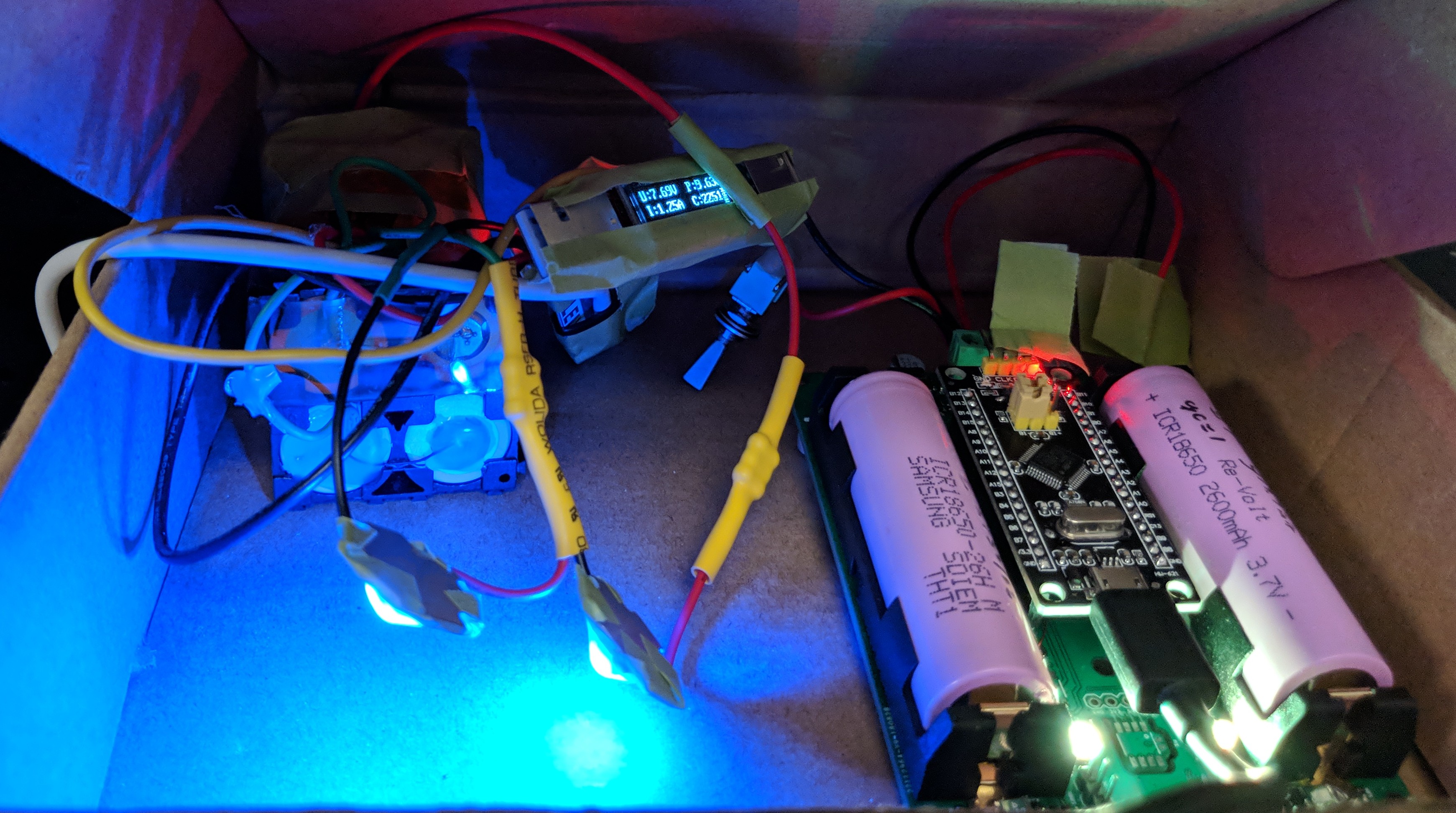

This is a project to create a regenerative capable dual slot 18650 Li-* battery tester, which when used in conjunction with computer software or an additional ESP8266 module (yet to be implemented) can also graph the data in real time to Thingspeak or InfluxDB/Grafana for analysis.

List of Features

Version 1 - Regenerative Only

- Voltage Range (Charge): 0-4.35V

- Max Current (Charge): 1.5A

- Max Current (Discharge): 1.5A

- Sample Rate: 1 Hz (Reporting rate), 2 kHz (Loop/Integration rate)

- Efficiency: 84% (Buck/charge mode, average, 1.5A output), 82.2% (Boost/discharge mode, average, 1.5A output)

Version 2 - Regenerative Mode

High Power Variant

- Charge: Up to 5A (tbd)

- Discharge: Up to 5A (tbd)

Low Power Variant

- Charge: Up to 1.5A

- Discharge: Up to 1.5A

Version 2 - Non-regenerative Mode

High Power Variant

- Charge: Up to 5A (tbd)

- Discharge: Up to 5A (single channel), 3A (dual channel)

Low Power Variant

- Charge: Up to 1.5A

- Discharge: Up to 3A

Output Format

State List:

- 0. Battery Disconnected (Unused)

- 1. Battery Discharge

- Voltage < 2.75V?

- 2. Battery Disconnected

- Wait 5 minutes

- 3. Battery Charge

- Current < 50mA?

- 4. Battery Disconnect

- 5. Wait 1 minute

- 6. Measure IR

- 7. Measure IR

- Wait 10 seconds

- 8. Parking

Message Type List:

- 0. Cell 1 periodic status

- 1. Cell 1 end of discharge stats

- 2. Cell 1 end of charge stats

- 3. Cell 1 IR debug

- 4. Buffer pack voltage/system status

- 5. Cell 2 periodic status

- 6. Cell 2 end of discharge stats

- 7. Cell 2 end of charge stats

- 8. Cell 2 IR debug

| Message Type (Periodic Status) | Battery Voltage (mV) | Battery Current (mA) | Capacity (mAH) | Capacity (mWH) | Temperature (C) | State |

| 0 | 3752 | 1499 | 648 | 2565 | 23.6 | 1 |

| 5 | 3942 | -1454 | 980 | 3658 | 25.8 | 3 |

| Message Type (End of Discharge) | Battery Voltage (mV) | Battery Internal Resistance (mOhm) | Capacity (mAH) | Capacity (mWH) | Temperature (C) | State |

| 1 | 3015 | 149.3 | 648 | 2565 | 23.6 | 2 |

| 6 | 2975 | 45.2 | 2012 | 7518 | 27.3 | 2 |

| Message Type (End of Charge) | Battery Voltage (mV) | Battery Internal Resistance (mOhm) | Capacity (mAH) | Capacity (mWH) | Temperature (C) | State |

| 2 | 4109 | 105.4 | 980 | 3658 | 25.8 | 7 |

| 7 | 4103 | 48.4 | 1780 | 6507 | 28.4 | 7 |

Heatsink Sizing

The cooling solution for the 2 MOSFETs that make up the discharging circuit is a 100x40x20mm aluminum extruded heatsink with 11 fins, and a 5V 40x40x20mm fan. Results are as follows (tested at ~21 C ambient):

- 4A 4.2V (16.8W) (2A x2) - 65 C max on FET body, approx. 71.3 C Tj

- 5A 4.2V (21W) (2.5A x2) - 75 C max on FET body, approx. 82.9 C Tj

- 6A 4.2V (25.2W) (3A x2) - 84 C max on FET body, approx. 93.5 C Tj

- 7A 4.2V (29.4W) (3.5A x2) - 93 C max on FET body, approx. 104 C Tj

- 4A 4.2V (16.8W) (4A x1) - 79 C max on FET body, approx. 91.6 C Tj

- 5A 4.2V (21W) (5A x1) - 93 C max on FET body, approx. 108.8 C Tj

Electronics

Buck Converter (Charger)

...

Boost Converter (Discharger, regenerative)

...

Constant Current Load (v2 Discharger, resistive)

...

Microcontroller

The CCR uses an STM32F103C8 microcontroller in the form of a "blue pill" board, which includes crystals, header pins, USB plug, and other supporting circuitry, and allows for the MCU to be swapped out in case of damage.

Hardware Revisions

Revision 1.0

This is the first revision of the CCR, which only natively supports regenerative discharging mode.

Errata:

- Pin A12 was used for the P-channel MOSFET control on cell 2, which is not usable for this function (pin is natively used as USB D+).

- ...

Revision 2.0

This is the second revision of the CCR, which supports regenerative discharging mode (optional) as well as constant current discharging mode, and increased current capability of up to 3A in charge, and 5A (single channel)/3A (dual channel) in discharge.

Change List:

- ...

Errata:

- ...

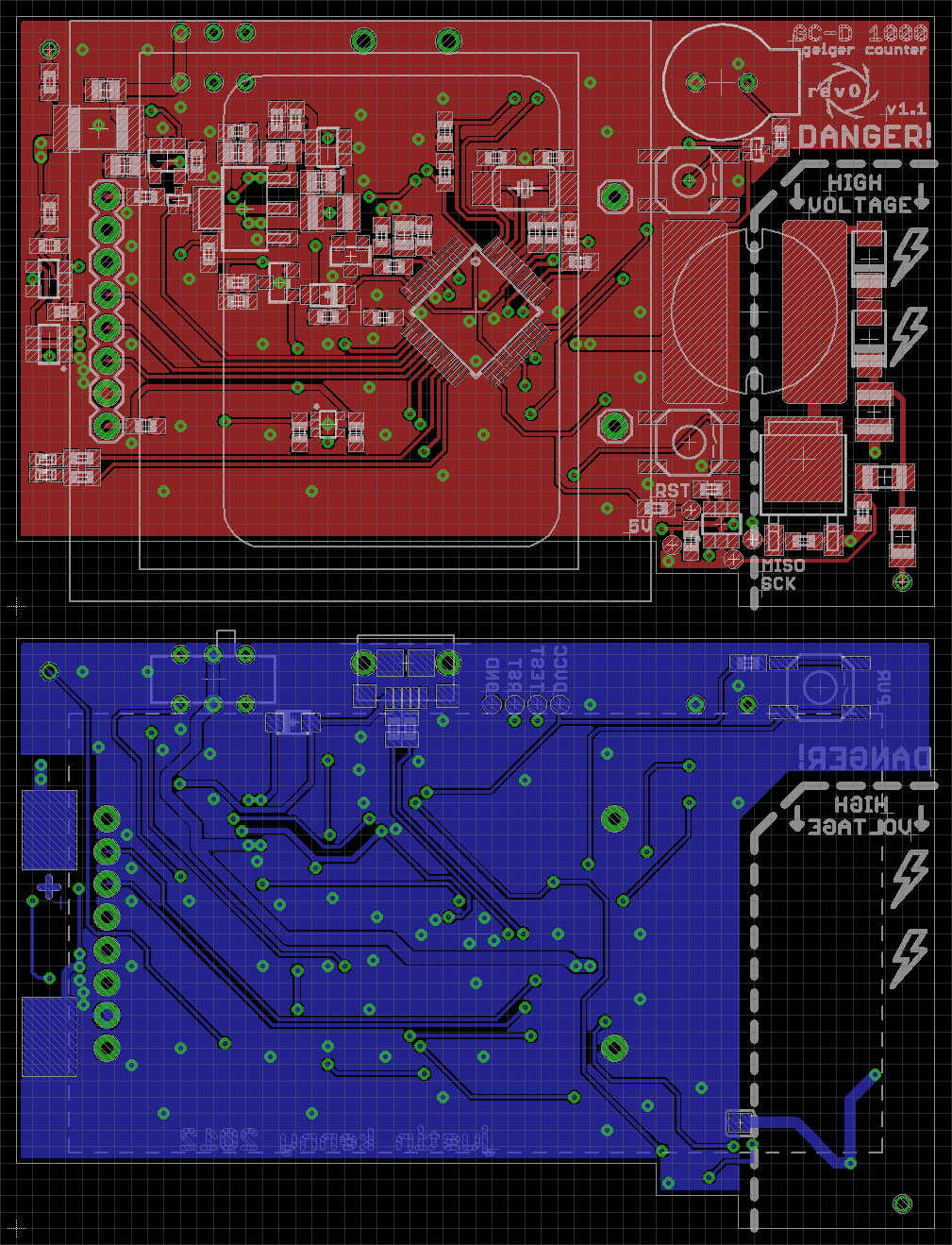

PCB Files

Here is the Eagle schematic file for the CCR v1.0: http://rev0proto.com/files/tbd.sch Here is the Eagle board file for the CCR v1.0: http://rev0proto.com/files/tbd.brd

Enclosure

The enclosure for the CCR v2.0 was created in Fusion 360 and is made up of x pieces which can be 3D printed and assembled with M3 screws.

Here are the Fusion 360 files for the CCR v2.0 enclosure: http://rev0proto.com/files/tbd.zip

Code

Full source code for the project can be found here: http://rev0proto.com/files/x.zip

Videos

<HTML5video type="youtube" width="400" height="300" autoplay="false">1SHY4jAfTcM</HTML5video> <HTML5video type="youtube" width="400" height="300" autoplay="false">nnFNTOPaNV0</HTML5video>

Photos

Total Project Cost

| Component | Cost | Source |

| Enclosure (Top) | $19.03 | Shapeways |

| Enclosure (Bottom) | $22.33 | Shapeways |

| Enclosure (Buttons/Switch/Cover/Shipping) | $20.65 | Shapeways 123 |

| PCB | $8.40 | OSH Park |

| Geiger Tube | $7.44 | eBay |

| Battery | $4.04 | HobbyKing |

| Components | $25.86 | Digi-Key |

| Total Price | $107.75 |